Iron Casting

SiMo

Technical Specifications

| Material Code | No. | Silicium (%) | Molybdenum (%) |

| EN-GJS-SiMo25-5 | 53.111 | 2,3 – 2,7 | 0,4 – 0,6 |

| EN-GJS-SiMo30-7 | 53.112 | 2,8 – 3,2 | 0,6 – 0,8 |

| EN-GJS-SiMo35-5 | 53.113 | 3,3 – 3,7 | 0,4 – 0,6 |

| EN-GJS-SiMo40-6 | 53.114 | 3,8 – 4,2 | 0,5 – 0,7 |

| EN-GJS-SiMo40-10 | 53.115 | 0,8 – 1,1 | |

| EN-GJS-SiMo45-6 | 53.116 | 4,3 – 4,7 | 0,5 – 0,7 |

| EN-GJS-SiMo45-10 | 53.117 | 0,8 – 1,1 | |

| EN-GJS-SiMo50-6 | 53.118 | 4,8 – 5,2 | 0,5 – 0,7 |

| EN-GJS-SiMo50-10 | 53.119 | 0,8 – 1,1 |

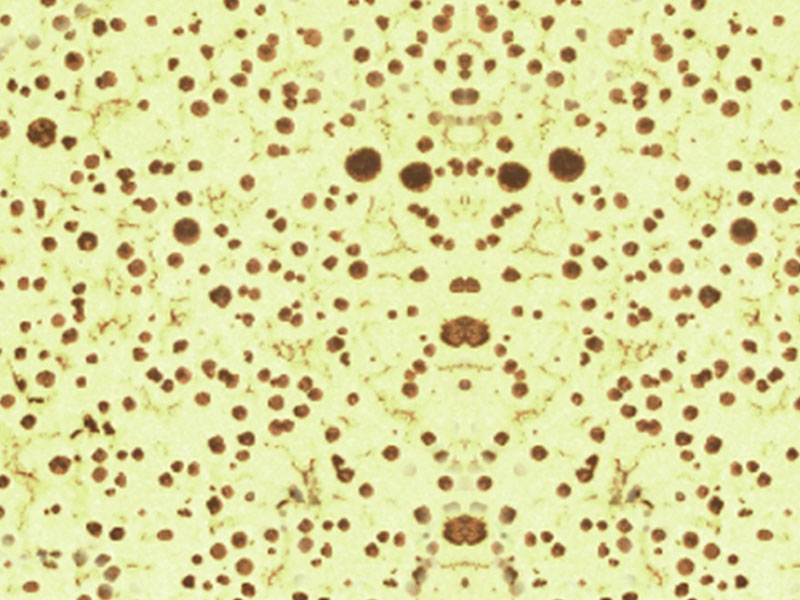

Similar to SSF ductile irons, SiMo alloyed ductile irons with high silicium have a relatively ductile matrix structure due to their ferritic structure. High silicium increases the stability of the material at high temperature, both by promoting a ferritic microstructure and increasing the austenite (eutectoid) transformation temperature. Thanks to the solid solution hardening obtained as a result of high silicium, a significant increase especially in yield strength rather than tensile strength can be observed. As a final note, SiMo alloyed ferritic ductile cast irons exhibit a higher resistance to creep at high temperatures..